Turnkey Solution for Chemical Manufacturing Plant

1. Project Details:

Industry: Chemical

Location: Dahej, Gujarat

Project Duration: 6 months

Team: Client – 2 engineers; MWA: 2 engineers

Need of the project:

- Expansion due to higher production demand

- Automation system for continuous critical process plant without loss of data.

2. The Problem:

- Due to critical process plant any shutdown in the system would lead to huge losses and rejection of batch product

- Improvement in bottom line with proper decision making

- Reduction in power cost

3. The Solution:

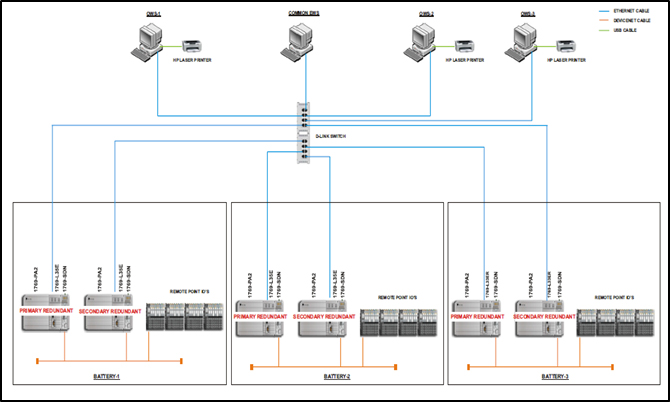

- Compact Logix HOT Redundant PLC system over DEVICENET communication to avoid system failure and loss of data.

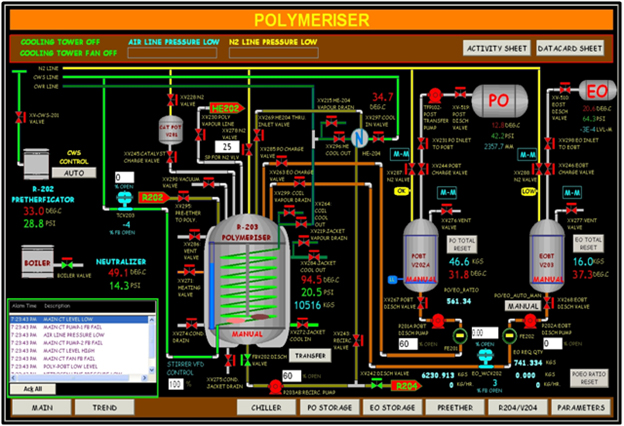

- FactoryTalk SCADA based system for Visualization of plant.

- FactoryTalk VantagePoint to provide information that enables analysis and helps manage manufacturing consistency, energy use and other factors that can improve the bottom line

Features Offered:

- SMS alerts for critical data

- Customized batch reports

- Database connectivity & data exchange between Manufacturing plant in one state & head office in other state of India.

Scope of Work:

- Designing, Erection & Commissioning of Automation System

- Laying & termination of instrumentation cables – Power, control, signal and earthling cables.

- Supply and installation of instruments: Valves, Transmitters, Cable tray, Conduits, glands etc..

- Supply and installation of JB’s, FLP Boxes, Cable tray, Conduits, glands etc..

BOM:

- PLC Control Panel – 1 Set

- RIO Control Panel – 1 Set

- Weight Indicator – 10 Nos

- Load Cells – 30 Nos

- Flow Transmitter – 4 Nos

- Level Transmitter – 3 Nos

- Level Transmitter DP type – 10 Nos

- Pressure Transmitter – 6 Nos

- Temperature Transmitter – 8 Nos

- Temperature Element PT100 – 12 Nos

- Control Valve – 4 Nos

- On-Off Valve – 90 Nos

- Three Way Valve – 5 Nos

- Flow Switch – 2 Nos

- Pressure Switch – 6 Nos

- Level Switch – 3 Nos

Main PLC panel - Limit Switch – 3 Nos

- Magnetic Type Level Gauge – 8 Nos

- Temperature Gauge – 20 Nos

- Pressure Gauge – 12 Nos

- Temp. Scanner 16 Inputs – 3 Nos

- Junction Boxes – 8 Nos

- FLP Boxes – 10 Nos

- Commercial Grade Computers – 3 Nos

4. The Results:

- Production demands are met leading to higher revenue

- 6-8% power saving resulting in around a profit of Rs. 5-6 Lakhs

- Better decision making has helped locate and correct sources of inefficiencies quickly leading to better bottom line